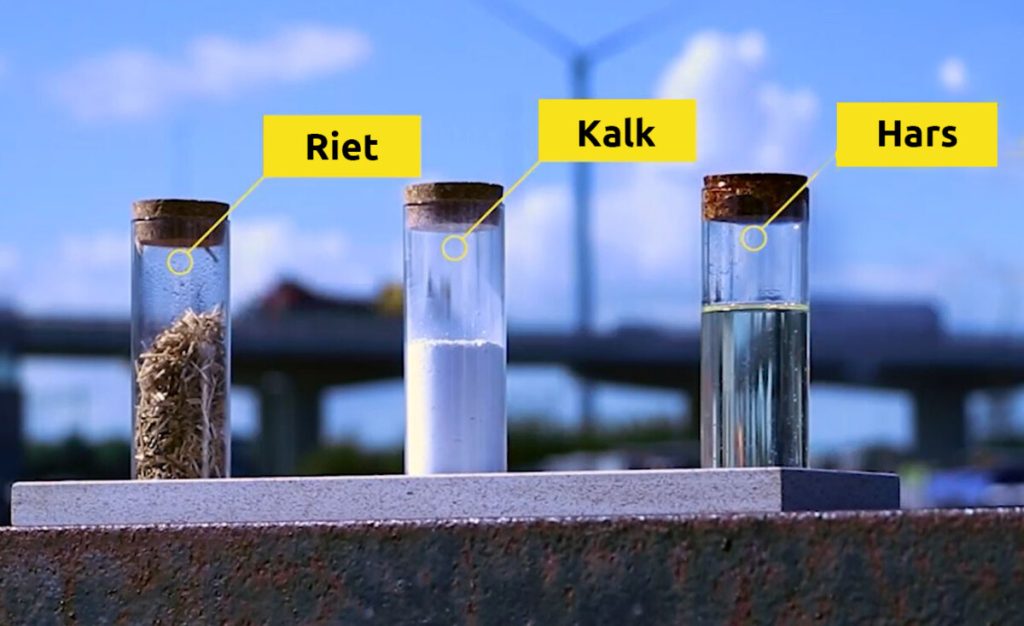

Making Nabasco® biocomposite traffic signs can be compared to baking a loaf of bread. The ingredients of the biocomposite are kneaded into a kind of dough/paste. A small amount of graphite is added to this mixture of reed, lime and resin; this gives the traffic sign its prescribed color. The dough ripens for some time. The exact weight of dough required for the relevant traffic sign model is determined (0% waste), after which the composite is pressed under high pressure and at a high temperature. Air disappears under the pressure, the composite transforms from malleable to extremely hard, durable, weather-resistant and dimensionally stable. The CO2 of the reed is locked up and the production process is done with self-generated green electricity. This way, a top product is produced in a very environmentally.

The video explains the general process in a ‘prototype’ lab scale setting.